The milk powder lid is a critical packaging component designed to protect product nutrition, ensure hygiene, and enhance consumer convenience. As global demand for infant formula and nutritional dairy products continues growing, the performance and reliability of packaging lids directly influence product marketability and brand trust. In large-scale industrial production, the lid’s design and compatibility also affect filling efficiency, sealing quality, and supply chain consistency.

The Importance of Milk Powder Lids in Modern Food Packaging

Milk powder packaging requires airtight protection to preserve sensitive nutrients and prevent moisture intrusion. As packaging automation evolves and regulatory standards tighten, the milk powder lid has become a key element that supports:

• Hygienic sealing for long-term storage stability

• Transport protection through robust structural strength

• Re-closeable convenience for consumer usage scenarios

• Regulatory compliance for food-contact safety

Performance growth in packaging components continues to play a major role in global dairy competitiveness.

Types of Milk Powder Lids and Functional Advantages

Different lid designs support different market segments and packaging strategies. Product categories with strong global demand include:

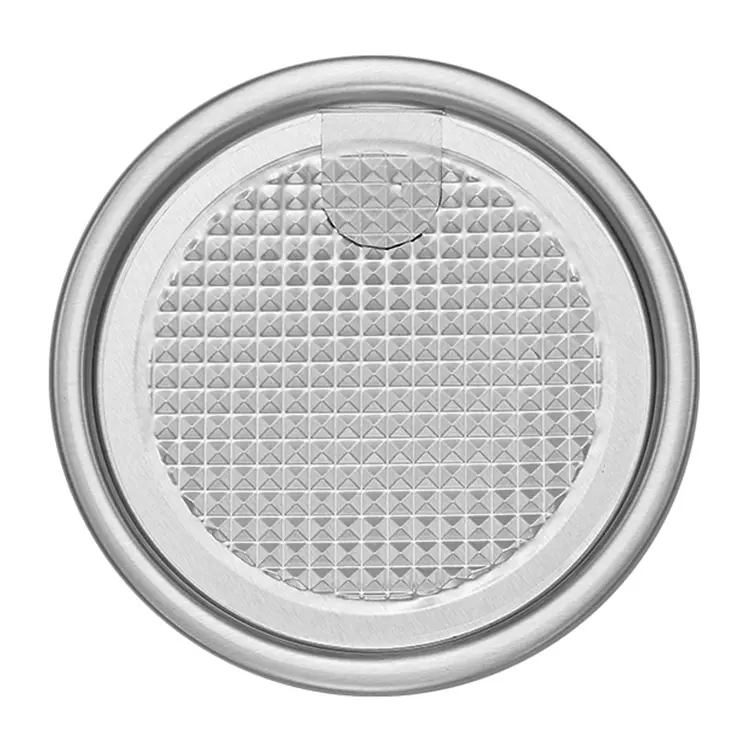

• Full-open metal lids for wide product access

• Easy-open ends (EOE) with optimized pull-ring design

• Plastic overcaps for secure resealing after first opening

• Scoop-integrated lids improving end-user convenience, especially in infant nutrition

These packaging options enhance hygiene while differentiating retail presentation in competitive dairy markets.

Technical Specifications Prioritized in Industrial Procurement

Milk powder lids must support extreme freshness control while maintaining consistent compatibility with automated equipment. Key performance criteria include:

• High-precision sealing preventing oxidation and bacterial exposure

• Durable tinplate or aluminum material with corrosion resistance

• Food-grade internal coating preventing chemical migration

• Seam-fit accuracy for smooth line operation and lower downtime

• Mechanical strength supporting stacking and long-distance shipping

• Flexible specification range (99–189 mm commonly for dairy cans)

• Tamper-evident safety elements enhancing consumer confidence

• Customized branding options such as embossing and ring-color differentiation

These specifications ensure smooth production and strong shelf appeal.

Hygiene and Regulatory Compliance for International Dairy Brands

Because the lid directly influences food safety, compliance must be verifiable and traceable. Industrial buyers focus on:

• FDA / EU food-contact standards for global sales

• BPA-free coating options

• ISO-certified food packaging quality management

• Full batch traceability for regulatory inspections

• Visual inspection systems and defect elimination protocols

Compliance-ready lids support entry into tightly regulated infant nutrition markets.

Global Demand Growth in Dairy and Nutrition Packaging

Widespread application areas include:

• Infant formula packaging

• Whole milk powder and skimmed milk powder

• Protein powders and sports nutrition products

• Medical dietary and specialized nutrition formulas

• Institutional dairy supply packaging

Expansion of dairy consumption in Asia-Pacific, Latin America, and Middle East markets continues to drive demand for high-performance lid solutions that support brand value and consumer protection.

Quality Consistency and Manufacturing Stability

Manufacturing consistency determines whether lids can deliver continuous safety and quality throughout product lifecycles. Industrial evaluation focuses on:

• Dimensional precision ensuring stable seaming

• Hygienic coating endurance under long-term storage

• Pull-ring ergonomic performance ensuring smooth opening

• No burrs or sharp edges to protect consumers and production staff

• Stable surface quality maintaining brand-identical appearance across batches

• Long-duration compatibility with high-speed packaging lines

Stable production performance translates into reduced recall risk and improved operational certainty.

Packaging Innovation and Sustainability Direction

Leading trends in lid development align with responsible growth in dairy packaging:

• Lightweighting strategies reduce raw material usage

• Recyclable metal content contributing to circular design targets

• Opening convenience upgrades requiring fewer accessories or tools

• Cleaner re-sealing designs preventing contamination after opening

• Waste management improvement through easy component separation

These upgrades help brands meet environmental compliance and improve customer perception.

Supply Chain Assurance in Bulk Procurement

Reliable and continuous lid supply helps prevent costly interruptions in dairy production. Procurement teams pay attention to:

• Production scale supporting multi-country distribution

• Inventory management suitable for continuous filling operations

• Packaging automation compatibility minimizing line adjustments

• Stable raw material sourcing reducing price volatility risk

• Long-term order planning ensuring supply continuity in peak seasons

An efficient and resilient supply chain improves overall cost performance and competitive capability.

Summary

The milk powder lid is far more than a closure—it is a structural and hygienic component supporting product freshness, operational efficiency, and consumer trust. By prioritizing performance standards, compliance readiness, packaging adaptability, and reliable supply capability, B2B buyers can secure a long-term packaging solution that enhances brand integrity and market success.

As the dairy nutrition industry continues expanding globally, high-quality milk powder lids will remain an essential foundation for packaging innovation, product safety, and manufacturing productivity.

FAQ

Q1: What are the most common sizes of milk powder lids?

Standard diameters range from 99 mm to 189 mm according to can volume and production requirements.

Q2: What lid features benefit infant formula packaging?

Moisture-resistant sealing, safe internal coatings, and re-closure overcaps are essential for sensitive nutrition products.

Q3: Can milk powder lids support brand customization?

Yes. Embossing, color-coded rings, surface printing, and textured finishes are widely available.

Q4: Which materials are typically used?

Tinplate and aluminum are preferred due to high sealing performance and global recyclability acceptance.

Post time: Dec-05-2025