In today’s competitive canned food and beverage industry, packaging innovation is crucial to meet consumer demands for convenience, safety, and quality. The Tinplate FA Full Aperture Easy Open End has emerged as a key solution, offering superior usability and reliability. This advanced can end design enhances product accessibility, reduces consumer effort, and ensures high standards of hygiene and freshness. For B2B manufacturers, suppliers, and distributors, understanding the advantages and applications of this packaging component is essential to maintain a competitive edge in the market.

Understanding Tinplate FA Full Aperture Easy Open End

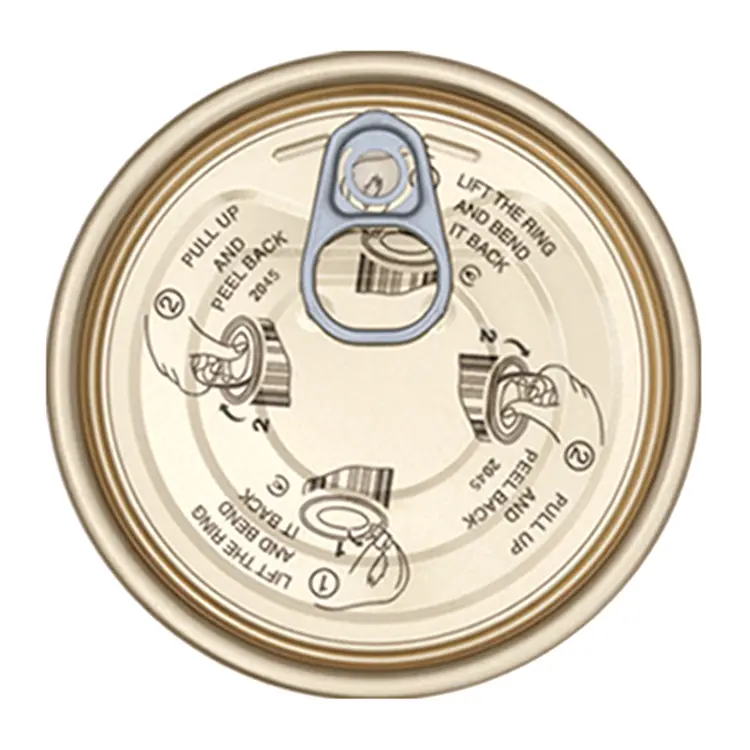

The FA Full Aperture Easy Open End refers to a tinplate can lid that opens completely when the pull-tab is lifted, creating a full opening across the can’s surface. Unlike standard ends that leave a partial opening, the FA design ensures that the entire product content is easily accessible without additional tools. This type of can end is widely used in beverages, ready-to-eat foods, pet foods, and other liquid or semi-solid products where ease of access and consumer satisfaction are priorities.

Key features include:

● Full aperture opening for complete content access

● Pull-tab mechanism for effortless opening

● High-strength tinplate construction for durability and corrosion resistance

● Hygienic design to maintain product safety and quality

● Compatibility with automated canning lines

Advantages of Using Tinplate FA Full Aperture Easy Open End

For B2B beverage and food manufacturers, the FA full aperture easy open end offers numerous operational and marketing benefits:

Enhanced Consumer Convenience

● Effortless opening: The pull-tab design eliminates the need for can openers

● Full access: Consumers can pour, scoop, or consume the entire content easily

● Ideal for on-the-go use: Perfect for single-serve beverages or ready-to-eat meals

Product Safety and Integrity

● Hygienic sealing: Maintains freshness, prevents contamination, and extends shelf life

● Leak prevention: Strong tinplate construction minimizes accidental leakage

● Tamper evidence: Any interference with the seal is easily noticeable

Operational Efficiency

● Automated production: Compatible with high-speed filling and seaming machines

● Reduced product waste: Full aperture access ensures that no residue remains in the can

● Cost-effective: Lightweight yet durable tinplate reduces packaging and transport costs

Market Appeal

● Modern packaging: Enhances product aesthetics and brand perception

● Promotional opportunities: Full-surface printing and labeling for brand visibility

● Differentiation: Stands out on shelves due to functional convenience

Applications of Tinplate FA Full Aperture Easy Open End

The versatility of Tinplate FA Full Aperture Easy Open End makes it suitable for a wide range of canned products in the B2B sector:

● Beverages: Carbonated drinks, juices, energy drinks, and ready-to-drink coffee or tea

● Ready-to-eat meals: Soups, pasta, stews, and sauces

● Pet food: Wet pet food requiring easy access for consumers

● Specialty foods: Pickles, canned fruits, vegetables, and desserts

By selecting this type of easy open end, manufacturers can provide a premium user experience while maintaining efficiency in production and distribution.

Selecting the Right FA Full Aperture Easy Open End

When sourcing Tinplate FA Full Aperture Easy Open Ends, B2B companies should evaluate the following factors:

● Size and compatibility: Match the end diameter with your can body

● Material quality: Ensure corrosion resistance and structural integrity with high-grade tinplate

● Pull-tab design: Choose standard or reinforced tabs depending on product viscosity

● Supplier reliability: Look for manufacturers with consistent quality, timely delivery, and technical support

● Printing and branding: Consider customizable surfaces for promotional or private-label products

These considerations help ensure seamless production, maintain product quality, and enhance consumer satisfaction.

FAQ: Tinplate FA Full Aperture Easy Open End

Q1: Are FA full aperture easy open ends compatible with automated canning lines?

A1: Yes, these ends are designed for high-speed automated seaming machines, ensuring efficient production at scale.

Q2: Can FA easy open ends maintain beverage or food freshness?

A2: Absolutely. The tinplate construction and airtight seal preserve freshness, flavor, and nutritional quality.

Q3: Are these easy open ends suitable for both liquids and semi-solids?

A3: Yes, they are ideal for beverages, soups, sauces, pet foods, and other semi-solid products.

Q4: Can these can ends be customized for branding purposes?

A4: Yes, the tinplate surface supports full-body printing, embossing, and labeling, allowing effective brand promotion.

Conclusion

The Tinplate FA Full Aperture Easy Open End represents a modern and essential packaging solution for B2B food and beverage manufacturers. Its full aperture design, consumer convenience, product safety features, and operational efficiency make it a strategic choice for businesses looking to enhance both production workflows and consumer experience. By adopting this easy open end technology, manufacturers and distributors can differentiate their products, streamline operations, and maintain high standards of quality and sustainability. For brands seeking to improve accessibility, market appeal, and efficiency, investing in Tinplate FA Full Aperture Easy Open Ends is a smart and commercially valuable decision.

Post time: Jan-21-2026