Full aperture end (FAE) technology is becoming increasingly important in the beverage packaging industry, especially for aluminum and tinplate cans. These can ends allow consumers to access the entire surface of the container, improving usability and the overall drinking experience. For B2B businesses in the beverage and packaging supply chain, understanding their specifications, manufacturing processes, and benefits is essential to ensure efficiency, safety, and customer satisfaction.

FAE technology is not just a trend; it addresses the need for safer, faster, and more sustainable packaging. These ends reduce the risk of sharp edges, improve can opening performance, and allow innovative designs for beverages ranging from soft drinks to craft beers. Sourcing high-quality full aperture ends helps businesses streamline production, reduce downtime, and maintain consistent quality in large-scale operations.

Understanding Full Aperture Ends

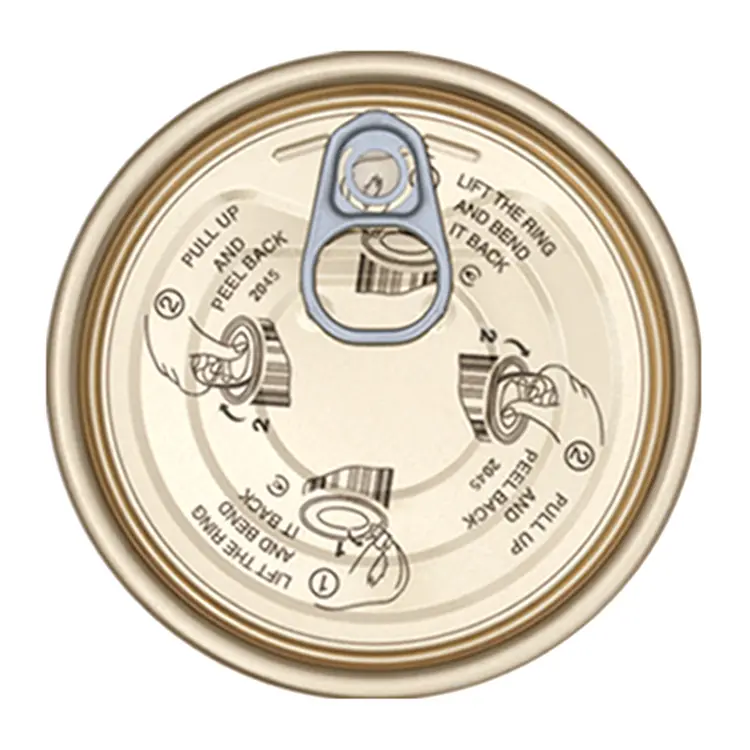

A full aperture end is a type of can lid that removes the entire top portion of the can when opened. Unlike traditional pull-tab designs that leave a small section attached, FAEs provide a fully open surface, enhancing accessibility and safety.

These ends combine precision engineering, durable materials, and advanced production techniques. They must withstand internal pressure from carbonated beverages, resist deformation during transport, and deliver consistent opening performance across millions of cans.

Types of Full Aperture Ends

● Tinplate Full Aperture Ends – Durable and corrosion-resistant, ideal for carbonated beverages and soft drinks.

● Aluminum Full Aperture Ends – Lightweight, suitable for energy drinks, juices, and craft beverages; also fully recyclable.

● Easy Open Full Aperture Ends – Pre-scored and equipped with pull tabs for smooth, tool-free opening.

● Customizable Ends – OEM solutions allow unique diameters, tab designs, and branding to match specific cans and marketing strategies.

Key Features to Consider

● Material Quality – High-strength aluminum or tinplate ensures durability, safety, and resistance to beverage pressure.

● Scoring Precision – Accurate pre-scoring guarantees smooth and consistent opening without sharp edges.

● Pull Tab Design – Ergonomic tabs improve the consumer experience by reducing opening effort.

● Pressure Resistance – Ends must withstand carbonation pressure to prevent deformation or rupture.

● Compatibility – Must match can diameter, wall thickness, and filling process for proper sealing and production efficiency.

Advantages of Full Aperture Ends

● Enhanced Consumer Experience – Fully open surfaces allow easy access, reducing spillage and improving satisfaction.

● Improved Safety – Properly engineered ends reduce the risk of injury from sharp edges.

● Streamlined Production – Consistent quality and precise scoring reduce downtime and minimize rejection rates.

● Brand Differentiation – Customizable designs and tab shapes support marketing strategies and create visually appealing packaging.

● Sustainability – Aluminum and tinplate ends are fully recyclable, supporting environmental initiatives.

Applications of Full Aperture Ends

● Soft Drinks – Smooth and safe opening for carbonated beverages under high pressure.

● Beer and Alcoholic Beverages – Fully accessible tops for pouring, tasting, or drinking directly from the can.

● Energy Drinks and Functional Beverages – Lightweight aluminum ends for portability and convenience.

● Juices and Ready-to-Drink Products – Smooth opening, especially for single-serve or family-sized cans.

● Craft and Specialty Beverages – Customizable ends allow unique branding and innovative designs to stand out in the market.

Manufacturing and Quality Considerations

● Stamping and Scoring – High-precision dies cut and pre-score metal for uniform, easy opening.

● Surface Coating – Protective layers enhance corrosion resistance and prevent contamination.

● Pull Tab Assembly – Securely attached ergonomic tabs ensure consistent operation.

● Quality Inspection – Automated inspections verify pressure resistance, opening performance, and dimensional accuracy.

Selecting suppliers with advanced production technologies, certifications, and strict inspection ensures high-quality and reliable full aperture ends for large-scale operations.

Conclusion

Full aperture ends are a key innovation in the beverage packaging industry. They improve safety, consumer convenience, and production efficiency. For B2B buyers, sourcing high-quality FAEs ensures smooth operations, reduced downtime, and consistent product quality. Partnering with experienced suppliers who provide durable, precision-engineered, and customizable ends helps companies enhance operational efficiency, support sustainability, and deliver superior beverage experiences.

FAQ

1. What is a full aperture end?

A full aperture end is a can lid that removes the entire top surface when opened, providing complete access to the beverage and improving usability.

2. What types of full aperture ends are available?

Common types include tinplate, aluminum, easy open, and customizable full aperture ends for different beverage and production needs.

3. How do full aperture ends enhance safety?

Proper scoring, pull tab design, and high-quality materials reduce the risk of sharp edges and ensure smooth, controlled opening.

4. Why should B2B buyers choose high-quality full aperture ends?

High-quality ends ensure consistent opening performance, minimize production downtime, enhance the consumer experience, and support sustainability through recyclable materials.

Post time: Dec-08-2025