In today’s competitive packaging industry, can end manufacturing plays a pivotal role in ensuring product integrity, shelf life, and brand reliability. High-quality can ends not only protect contents but also streamline production processes, reduce waste, and meet global safety standards.

The Importance of Can End Manufacturing

Can ends are essential components in beverage, food, and aerosol packaging. Efficient manufacturing ensures tight sealing, consistent dimensions, and durability, which directly impacts customer satisfaction and operational efficiency.

Key Considerations in Can End Manufacturing

-

Material Selection – Aluminum, steel, or tinplate choices affect strength, corrosion resistance, and recyclability.

-

Precision Engineering – Advanced tooling guarantees uniformity, proper sealing, and leak prevention.

-

High-Speed Production – Modern equipment supports mass production without compromising quality.

-

Quality Assurance – Rigorous testing for thickness, strength, and surface finish ensures reliable performance.

-

Customization Options – Ability to produce ends for specialty cans, press-top designs, or unique closures.

Applications Across Industries

-

Beverage Industry – Carbonated drinks, juices, and energy drinks require precise sealing for freshness.

-

Food Packaging – Ready-to-eat meals, canned vegetables, and soups rely on durable can ends for long shelf life.

-

Aerosol Products – Aerosol sprays and personal care items need specialized can ends for pressure resistance.

-

Industrial Goods – Lubricants, chemicals, and paints often use reinforced can ends to prevent leaks and contamination.

Conclusion

Investing in advanced can end manufacturing ensures consistent quality, operational efficiency, and compliance with international standards. For B2B operations, partnering with experienced manufacturers reduces production risks, supports scalability, and enhances product reliability.

FAQ:

1. What materials are commonly used for can ends?

Aluminum, tinplate, and steel are most common, each offering unique advantages in strength, weight, and recyclability.

2. How is quality ensured in can end manufacturing?

Through precision tooling, rigorous testing, and consistent quality control processes.

3. Can manufacturers produce custom can ends for specific applications?

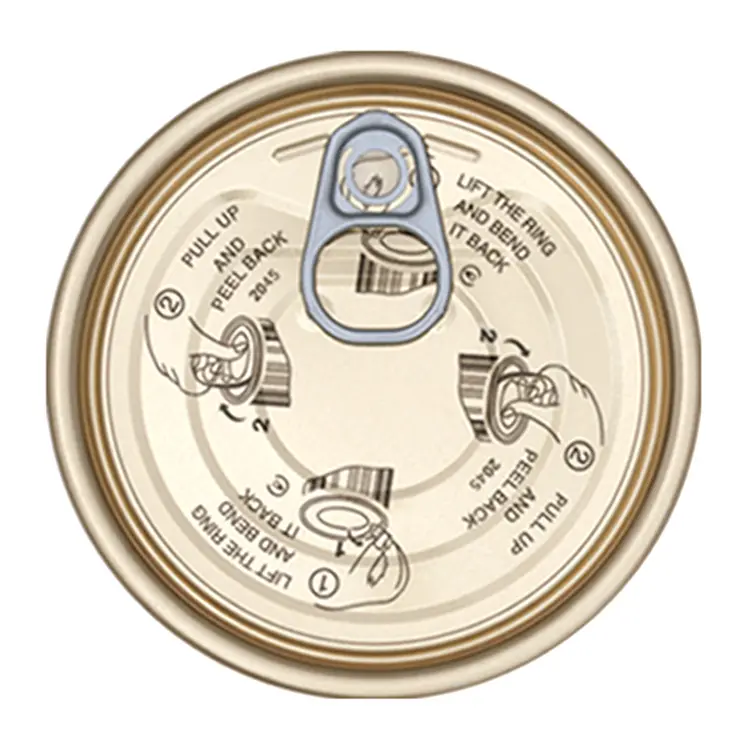

Yes, custom designs including press-top, pull-tab, or specialty closures are available.

4. How does can end quality affect product shelf life?

A properly manufactured can end ensures airtight sealing, preventing spoilage and extending product shelf life.

Post time: Oct-31-2025