The 603 153mm tinplate easy open end is a critical component in modern metal packaging, widely used for canned food, powdered drinks, and industrial products. For B2B buyers, manufacturers, and distributors in the food packaging supply chain, selecting high-quality easy open ends ensures airtight sealing, consumer convenience, and long-term product integrity.

What Is a 603 153mm Tinplate Easy Open End?

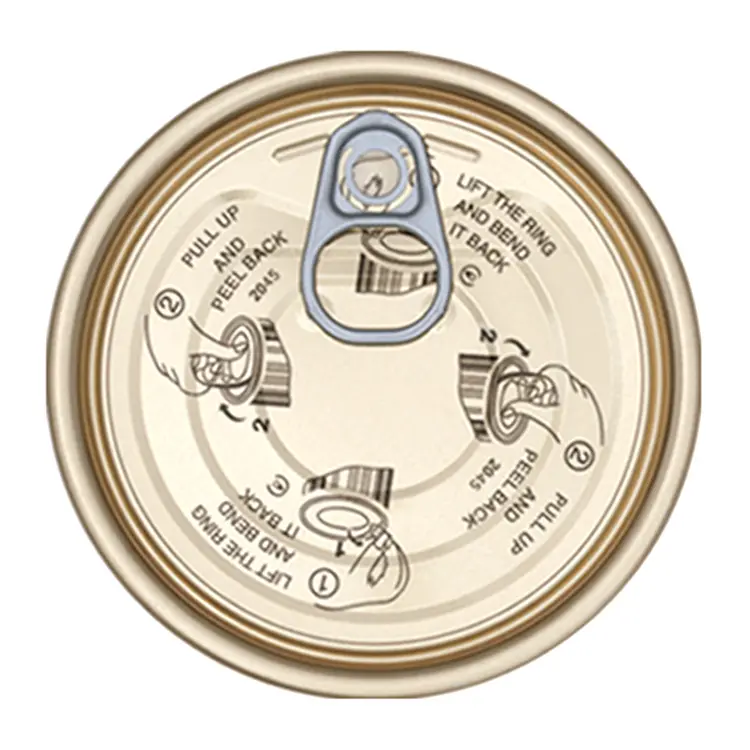

A 603 153mm tinplate easy open end refers to a circular metal lid made from tinplate (electrolytic tin-coated steel) with a diameter of 153mm. The “603” code represents the can end size based on the industry standard (Double Seam Can Dimension System). It features a pull-tab mechanism that allows consumers to open the can easily without any additional tools.

Key Features

-

Material: High-quality tinplate with excellent corrosion resistance.

-

Size: 603 (153mm diameter) suitable for large food and powdered cans.

-

Opening Type: Full aperture easy open design for maximum convenience.

-

Surface Finish: Can be customized with gold lacquer, silver, or BPA-NI coatings.

-

Sealing Compatibility: Suitable for double-seaming with metal or composite cans.

Why Tinplate Is Preferred for Easy Open Ends

Tinplate remains the top choice for easy open ends due to its combination of strength, formability, and food safety.

-

High barrier protection: Prevents oxygen, moisture, and light contamination.

-

Safe and hygienic: Meets global FDA and EU food-contact standards.

-

Excellent printability: Supports custom logo printing and branding.

-

Recyclable material: 100% eco-friendly and sustainable.

Applications of 603 153mm Tinplate Easy Open End

This can end size is mainly used in:

-

Canned food packaging: Milk powder, coffee, baby formula, nuts, and dry foods.

-

Beverage industry: Juice powder, tea mix, and malt drinks.

-

Industrial products: Paints, adhesives, or chemical powders.

-

Promotional packaging: Gift tins and specialty containers.

Benefits for B2B Buyers

For can manufacturers and brand owners, the 603 153mm easy open end offers key advantages:

-

Strong sealing performance ensures freshness and extended shelf life.

-

High production compatibility — suitable for automatic seaming machines.

-

Customizable branding — logo embossing, tab color, and surface finish available.

-

Reliable supply chain support — bulk export packaging with consistent quality control.

-

Certifications: ISO9001, SGS, and food-grade compliance.

Quality and Production Standards

Manufacturers follow strict quality management systems to ensure durability and consistency:

-

Material inspection: Tinplate thickness and coating uniformity check.

-

Forming precision: High-speed stamping lines ensure smooth ring and tab edges.

-

Pressure and leakage testing: Each batch is tested under simulated sealing pressure.

-

Visual and dimension inspection: Ensures conformity with international standards (BSI, DIN).

Conclusion

The 603 153mm tinplate easy open end represents the perfect balance of safety, convenience, and brand presentation in food and beverage packaging. Its excellent sealing capability, corrosion resistance, and adaptability make it a trusted choice for global packaging suppliers. For B2B clients, choosing a certified manufacturer guarantees product consistency, efficient production, and strong market competitiveness.

FAQ

1. What does “603 153mm” mean in can end size?

It refers to a can end diameter of 153mm, following the U.S. can dimension code “603” (6 and 3/16 inches).

2. What coating options are available for tinplate easy open ends?

Common options include gold lacquer, silver, epoxy phenolic, and BPA-NI coatings to meet different product needs.

3. Can these easy open ends be customized?

Yes, manufacturers can provide custom logo printing, tab color, embossing, and packaging solutions for branding.

4. What industries commonly use the 603 153mm EOE?

Mainly used in food, beverage, baby formula, coffee powder, and industrial can packaging.

Post time: Nov-10-2025